Lab-Scale Fermenter/Bioreactor System

BioTop® D with 2 reactor vessels,200mL-10L

Origin: China

Biotop® System Range

Equipment characteristics

The BioTop® range of fermenter/bioreactor systems is designed for consistent and optimum cell cultivation, maximum biological activity, ease-of-use and maximum flexibility. The BioTop® system range is used for scientific research, for process development work, for parallel experiments and for small-scale production. The BioTop® control module is operated from a laptop PC and each control module can control/monitor up to 2 autoclavable (glass) reactor vessels, with working volumes ranging from 200mL to 10L.

Pre-configured cell culture or microbial fermentation systems of various sizes are available.

In the standard configuration up to 8 selectable parameters can be controlled per vessel, for example1; agitation speed, temperature, pH, pO2, pCO2, foam/level, reactor fluid level, redox, dissolved oxygen, cell viability, optical density, and more (1. depending on sensors/instruments connected).

This flexibility allows you to monitor the parameters required for the perfect realization of your batch, fed-batch, continuous or perfusion process.

The BioTop® C configuration consists of 1 PC/HMI, 1 control module and 1 reactor vessel (single wall or double wall) with a working volume ranging from 200mL to 10L

The BioTop® D configuration consists of 1 PC/HMI, 1 control module and 2 reactor vessels (single wall or double wall), each with a working volume ranging from 200mL to 10L.

Biotop® Features

Reactor vessel

Autoclavable borosilicate glass, hemispherical round bottom;

single or double wall, with volume scale display.

Temperature control:

For single wall reactor vessels the temperature can be maintained using a cooling coil and an electrical heating plate or heating blanket.

For double wall reactor vessels there are connections provided for utilizing recirculating cooling/heating water. By connecting the reactor vessel to a recirculation thermostat unit with sufficient capacity, quick and accurate temperature control is achieved.

Aeration/Gas Control

For securing optimal cell cultivation or micro-bacterial fermentation a gas mixing station can be easily incorporated, for precise dosing and control of up to 4 gases (Air, O2, CO2 and N2) using either electronic controlled solenoid valves or manual controlled mass flow controllers.

Gas Sparger

Several types of spargers are available to supply the gases where needed (reactor surface and bottom), such as micro-bubble sparger, ring-sparger or nut-sparger.

Reflux Condenser

The reactor exhaust port is fitted with a condenser, in order to reduce the evaporation of culture medium and to help maintain a constant environment inside the reactor vessel.

Peristaltic Pump

|

Up to 4 peristaltic pumps can be used, with maximum pump speed of 60rpm and maximum pump capacity of 50mL/min. Selected pumps are suitable for long-term performance, working hours can be set. For higher pump capacities a separate pump can be connected/installed.

|

Impellers

Agitation or stirring is achieved using a mechanical direct-drive motor or a magnetic drive motor. For sealing the reactor securely when using the mechanical direct-drive motor, the rotating impeller shaft can be equipped with a single or double-seal sealing system.

Several types and sizes of impellers are available to provide optimum agitation, minimum shear-force and uniform and consistent reactor conditions during operation. Impeller types available are Marine, Rushton (4 or 6 blade), pitched-blade and more. Customized impellers can also be provided.

Option: Spin Filter

As an option, for continuous cell-culture perfusion processes the bioreactor may be equipped with a spin filter. Various filter diameters and pore sizes are available to best match your requirements and ensure optimal protection for the cells. The purpose of the spin filter is to remove culture media liquid from the reactor without harvesting the cells, thus allowing for addition of fresh culture media to ensure that optimum conditions for cell cultivation are maintained during continuous processing.

Reactor vessel head plate

|

The reactor vessel is closed at the top by a head plate with a central port for connection of the direct drive agitation motor. A magnetic drive agitation motor is optional. Around the central port are 11 configurable ports that may be used according to your requirements. Typically, these ports are used for connection of a condenser, reactor control sensors, product sampling and for supply of product, substrates, gases and/or additives. |

These ports are typically used for:

pH, DO, temperature sensor and other sensors (standard PG13.5 thread)

Sample extraction (removable septum)

Reactor fluid supply (product/inoculation, media, anti-foam, acid/alkali, etc)

Air filter

Air/gas supply (via surface or deep vessel spargers)

Reflux condenser

and more

Auto-control System

Control module The PLC equipped control module collects the measured data and ensures the correct operation and precision of the control loops.

HMI

The human/machine interface communicates via Ethernet with the control module PLC for exchanging the main data.

The operator and analysis software allows for real-time graphic monitoring and trend plotting. Several graphs can be displayed simultaneously. Numerous batch and event parameters are archived in the SQL database, essential for analysis and optimization of your process and for follow up of your culturing/fermentation experiments.

As an option, we can provide you with an all-in-one PC that is particularly powerful for heavy-duty (parallel processing) real-time operational data processing.

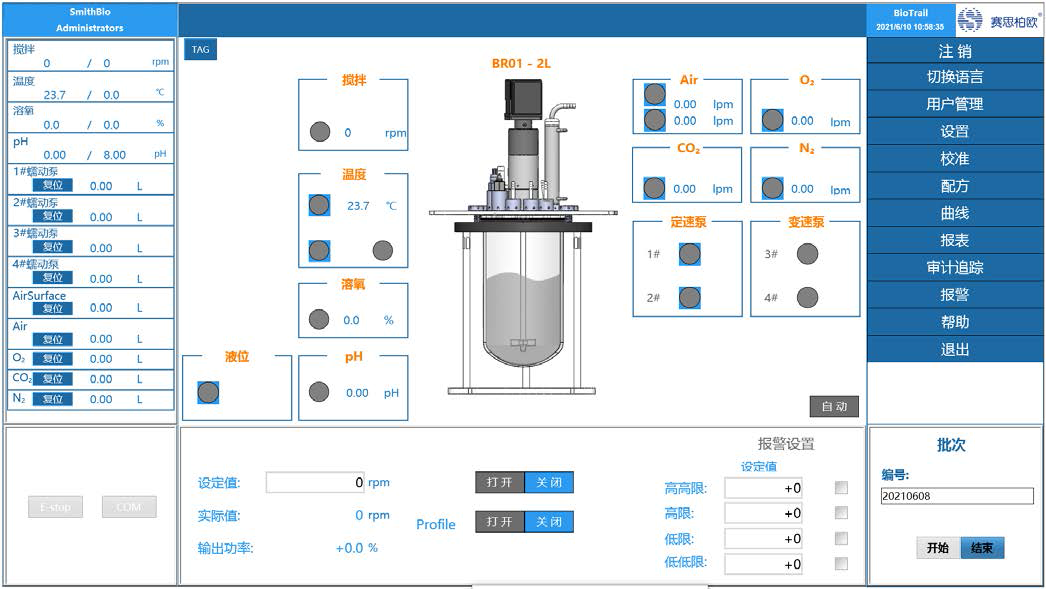

BioTrail™ auto-control software

The Bio Trail™ operation and control interface was developed to comply with the highest demands of the biotechnology industry.

The control module software is capable of operating and controlling multiple reactor vessels and/or connected instruments simultaneously. This feature may be used to operate multiple vessels for parallel experiments, and for connecting any external instrument or measuring devices such as biomass sensor, optical density sensor, gas analyzer and more.

This intuitive and easy to use operator software ensures optimum monitoring and control of your fermentation and cell culturing process and offers a number of advanced automation, process control and connectivity features:

● Use programmable process automation (editing and creating operation procedures)

● Simultaneous monitoring, control and display of up to 8 parameters such as temperature, pH, pO2, pCO2, dissolved oxygen, temperature, agitation speed, and more

● Simultaneous control of up to 6 reactor vessels from 1 PC-HMI

● Remote monitoring/control from any location

● User management (CFR21 part.11) features like e-signature and 4 level password authorization

● Use of mathematical formulas for optimizing process control strategies

● Create sophisticated process control strategies for optimizing harvesting and supply of gas/air and other utilities, energy and additives

● Real time or retrospective visualization of culture data in graphic or tabular format

● Up to 16 analog and 32 digital control signals can be managed simultaneously

● SCADA-SQL data management with batch reporting (Export/Import data in csv format)

The Bio Trail™ software is an intuitive interface that provides quick access to all your controllers’ parameters, to facilitate the management of your fermentation or cell culture process. A wide range of functions is available to assist you in all the key steps of the process, accessible in accordance with user authorization (by set password level):

|

Operator ● Start or stop a controller |

Engineer ● Create and change new controllers from the calculation module

|

Administrator |

|

Industry |

Applications ◆ Process Research & Development |

Operation mode ◆ Batch |

BioTop® System Range - Configuration overview

|

Reactor vessel |

||||||

|

Total volume |

250 mL |

500 mL |

1.5 L |

3 L |

7.5 L |

15 L |

|

Working volume |

200 mL |

400 mL |

1 L |

2 L |

5 L |

10 L |

|

Vessel type |

Autoclavable glass,single or double jacketed |

|||||

|

Head plate |

Stainless steel 316L |

|||||

|

No of ports |

12 | 12 | 12 | 12 | 12 | 12 |

|

Agitation system |

||||||

|

Type |

Top agitation, mechanical direct-drive with single or double seal, brushless motor, PID control (magnetic drive is optional) |

|||||

|

Speed |

0-300 rpm (cell culture)/0 - 800 rpm (fermentation) |

|||||

|

Impellers |

Marine / Pitched-Blade / Rushton / Others |

|||||

|

Configuration |

2 parts, removable |

|||||

|

Temperature control |

||||||

|

Heating |

Electrical heating plate or blanket (for single wall vessels) Water-bath heating (for double wall vessels) |

|||||

|

Cooling |

Cooling coil(for single wall vessels) Water-bath cooling(for double wall vessels) |

|||||

|

Sensors |

||||||

|

Temperature |

Pt100,A level,0-70 °C,special cables |

|||||

|

PH |

PG13.5,2-12,special cables |

|||||

|

DO (dissolved oxygen) |

PG13.5,0-200%,special cables |

|||||

|

Anti-foam |

Resistor,special cables |

|||||

|

Aeration |

||||||

|

Type or location for gas supply |

Surface or deep vessel aeration |

|||||

|

Gases |

Air,O2,CO2,N2 |

|||||

|

Control |

Mass flow meter(0-20 L/min) gas mixing ratio can be adjusted automatically |

|||||

|

Sparger types available |

Ring sparger/micro sparger |

|||||

|

Vessel exhaust |

Fitted with condenser(15L/min) |

|||||

|

Peristaltic pumps |

||||||

|

Number of pumps,maximum |

4(in addition,external pump can be added) |

|||||

|

Agitation speed,maximum |

60 rpm (working hours can be set) |

|||||

|

Flow rate,maximum |

50 ml/min (silicon tubing maximum inner diameter 4.8mm,wall thickness 1.6mm) |

|||||

|

Control system |

||||||

|

Controller |

PLC |

|||||

|

HMI |

21" touch screen PC display |

|||||

|

Software |

C-BIO 2TM |

|||||

|

Common facilities |

||||||

|

Electrical supply |

220V,50Hz |

|||||

|

Gas supply,max pressure |

0.5 bar,dry gas, particle-free, oil-free |

|||||

|

Cooling water,max pressure |

0.5 bar |

|||||

|

Drainage |

No back-pressure,natural straight line |

|||||

Optional instruments

1. Variable speed peristaltic pump

This reliable high precision pump is equipped with a 114DV four roller pump head and offers quick tube loading and manual and/or automatic variable speed control. The pump head can operate different tube (material) types with 1.6mm diameter, internal diameter ranging from 0.5 to 4.8mm. The maximum pump speed is 200rpm allowing for a maximum flow rate of 170ml/min with ± 1% accuracy. The quick and safe tube mounting system allows for installation in just a few seconds. This pump can be controlled locally or remotely.

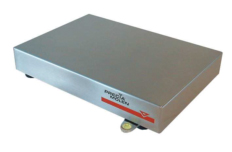

2、Weighing plate

Single-sensor tabletop weighing plate, especially designed for intensive use. The outside IP66 enclosure of this weighing plate is easy cleanable and made entirely of stainless steel (304L), particularly suitable for harsh environments or for use under stringent hygienic conditions. It meets the requirements of CE LNE 23948, electromagnetic compatibility 2004/108 /CE and low voltage 2006/95 /CE and can be cleaned/washed with water and/or detergents.

|

Range |

Δ |

HR |

325x225mm |

400x400mm |

500x400mm |

|

3 kg |

1 g |

0.1 g |

● |

x |

x |

|

6 kg |

2 g |

0.2 g |

● |

x |

x |

|

15 kg |

5 g |

0.5 g |

● |

x |

x |

|

30 kg |

10 g |

1 g |

x |

● |

● |

|

60 kg |

20 g |

2 g |

x |

● |

● |

3、On-line exhaust gas analyzer

We recommend and supply this precise, robust and easy to use gas analyzer that has a range of features.

Under BioTrail™ control, the CO2 and O2 concentrations in the fermentation exhaust are continuously on-line measured/archived and the relevant biomass parameters calculated. It allows for improved control in each phase of fermentation, and for timely and precise adjustment of ventilation and agitation speed. It can be of great significance for a better understanding and in-depth knowledge of the microbial fermentation process and allows for better control of the fermentation process.

|

Major parameter |

CO2 Infrared Absorption |

O2 Electrochemistry |

|

Range |

0-5 % |

0-30 % |

|

Resolution |

0.01% |

0.01% |

|

Precision |

+/-2% |

+/-2% |

|

Drifting scope |

<0.05% / month |

<0.05% / month |

|

Working temperature |

0-45°C |

0-45°C |

|

Response time T90 |

<50 secs |

<10 secs |

4. Thermostatic bath

We recommend and supply this circulating thermostatic bath which features the latest microprocessor technology.

Its integrated cooling system is suitable for constant water temperature control from 5°C to 35°C. This unit comprises a magnetic drive circulating pump, a water circulation cooling device, a cooling fan, a water circulation system, and a water level indicating device.

Rated power is 150W, effective head is 10M, effective flow is 10L/min, dimensions are 50x26x44cm (HxWxD)