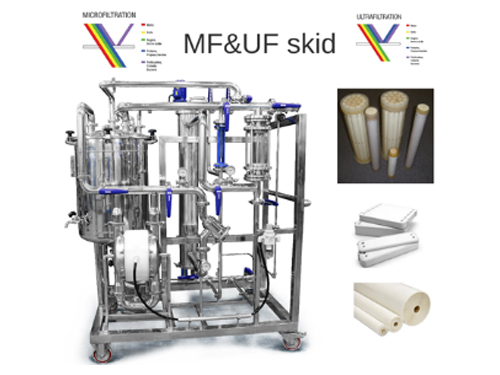

Ultrafiltration/Microfiltration System

Description

Sysbiotech’s ultrafiltration/microfiltration system uses Pall or other brands of tangential flow ultrafiltration/microfiltration membrane bags, or hollow fiber columns. brand. Each batch sizes can up over 1000L suitable for pilot and production scale, and can be customized according to user requirements. The design and engineering both are following cGMP requirements.

• The system can choose membrane or hollow fiber column

• Feed pressure, retentate pressure and permeate pressure can be measured

• Install manual or automatic valves, for controlling feed, retentate and permeate

• Measure feed flow, retentate flow and permeate flow

• Feed pump pressure up to 3barg

Automation

The controller for the TFF including 17” touch screen industrial PC and Phoenix or Siemens PLC controller with Fieldbus I/O boards. All electrical and pneumatic components are wired and tested. C-BioTM software according to GAMPV5 with TFF sequence has pre-loaded demonstration. PLC software according to ISA S88 is preloaded and tested.

Power components

Power supplies for instrumentation, switchgear, circuit breakers, and overload protection, and frequency inverter for pump.

Instrumentation

Temperature: Measurement and recording

Mass flow meter x 3: Measurement and recording for feed, retentate and permeate

Pressure sensor x 3: Measurement and recording for feed, retentate and permeate

Measurement control and recording of pump speed utilizing frequency inverter

C-BIO software features:

Universal control system for all ranges of volume and equipment

A separate control system for each equipment unit, or one control system for several units

The system is based on SCADA controller, constructed in conformance with industrial automation standards

Simple and intuitive user interface that provides quick access to all controllers and data

“Sequences” program allows creating your own program of cultivation, which will allow better control of the process

All process data is gathered and saved in separate electronic records

Four different levels of access are available to control the system