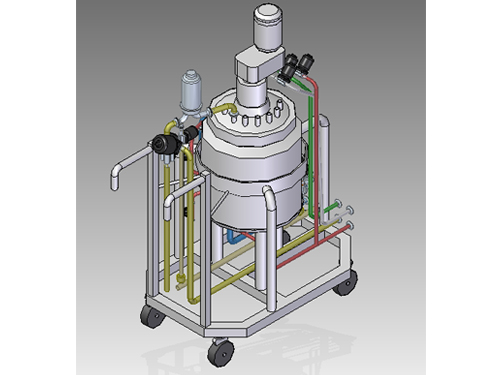

Obile CIP/SIP reactor 150L

Description

• Applications: Sterile media preparation and storage, feeding vessel, harvest vessel for culture fluid, buffer vessel, intermediate vessel for tangential flow filtration system or centrifugation

• Vessel is designed with the possibility of sterilization in place (SIP on place)

• The design of the vessel applied diaphragm (membrane ) valve on the product lines

• Vessel is equipped with a temperature sensor , pressure sensor , level sensor , pH sensor .

• In consultation with the client vessel can be equipped with additional sensors

• The design of vessel provides the ability to connect and clean in place CIP- mobile station

• Aseptic design

• Vessel is fully automated with SYSBIOTECH SCADA system

• The automation system meets all GMP requirements

• The automation system can automatically perform sterilization machine, clean in place (CIP) and other functions.

• The control system of technological parameters is based on the industrial automation systems to provide the necessary stability, flexibility and maintainability.

The control unit is mounted in a stainless steel box (1600x600x600), which contains the following components :

• electrical components

• Industrial computer PLC,

• Touch screen industrial computer with Phoenix PLC for process control including specialized software for process control.

Technical data

Dimension | Inner diameter is 500mm, external diameter is 650mm vessel body is 700mm, the total height with agitator and legs are around 1600mm |

Total volume | 150 liters |

Materials | AISI 316L for wetted parts AISI 304L for parts which is not in contact with the product |

Jacket | With insulation for temperature control |

Surface finish | The inner surface of less than 0.8 microns electropolishing |

Mixing system | Top mechanical agitator with single mechanical seal with impeller, speed range around 50-300rpm |

Ventilation system | With air filter (0,2 mkm) and necessary valves and devices |

Components: | Automatic valve for steam Automatic valve for washing solution Manometer Automatic harvest valve Sterilizable sampling valve The valve system for sterilization in place an empty vessel Sterile transfer line Cooling water supply system Temperature sensor Pressure Sensor Temperature control system with closed circuit through a heat exchanger Agitator port DN4” handhole DN80 sight glass with lamp DN2” Port with DN1” cleaning ball DN1 1/2” spare port Few numbers of DN1 1/2” Spare port Level sensor |

Features

Main features:

Fully automatic aseptic vessel

Can be use in combination with CIP-system

Vessels possible to integrate in technological system

Automatic SIP process

Automatic media in and out transfer

Mobile execution